Tightly’s product are used for high-reliability applications such as aerospace, automotive, consumer, and medical products. Electrically conductive adhesive products are primarily used for electronic applications where component need to be held in place and an electrical current can be passed between them. The broad portfolio of electrically conductive pastes is formulated using a variety of base chemistries including acrylate, epoxy, silver and silicone platforms. Understanding the tradeoff in values between these different chemistries is vital to satisfying your electronic packaging and assembly needs.

|

Specification / Model |

TY-001 |

TY-003 |

TY-004 |

TY-005 |

|

Composition |

Acrylic |

Silver |

Epoxy |

Silicone |

|

Features |

Low-temperature curing type can be used for Camera module |

High conductivity and excellent thermal conductivity |

Epoxies can be used in applications which are unsuitable for heating |

useful for EMI/RFI shielding and for antistatic. |

|

Appearance |

Silver |

Silver |

Silver |

Silver |

|

Viscosity(Pa.s) |

8000~15000 |

Paste |

Paste |

5000~8000 |

|

Curing Time |

120min/80℃ |

40min/120℃ |

A:B=7:1/48hrs |

5~10min/Surface |

|

Resistance |

< 5.0x 104 |

< 5.0x 104 |

< 5.0x 104 |

< 5.0x 104 |

|

Service Temperature |

0~300℃ |

0~300℃ |

0~300℃ |

0~250℃ |

|

Shelf Life |

6 Months |

6 Months |

6 Months |

6 Months |

Package:10g /100g /300g

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly's Die attach adhesives are essential materials in manufacturing internal components of many different electronic devices. Tightly offers excellent photo and thermal stability characteristics, with high adhesion strength over a wide range of temperatures. Tightly's advanced Die attach adhesives are increasingly accepted for demanding microelectronic semiconductor packaging as well as for chip on board assemblies. Our Die attach adhesive deliver reliable performance in extreme temperatures, high moisture, or stressful environments.

|

Specification / Model |

TY-051 |

TY-052 |

TY-054 |

TY-055 |

|

Composition |

Silicone |

Silicone |

Epoxy |

Epoxy |

|

Features |

High thermal conductivity and low thermal interface resistance |

High thermal conductivity, it can be for high-power LED die bonding |

To various metal, Outstanding heat-resistance and UV-resistance |

High electrical, thermal conductivity, to various metal |

|

Appearance |

White |

Transparent |

Transparent |

Silver |

|

Shore D |

72D |

72D |

72D |

72D |

|

Viscosity(mPa.s) |

18000~21000 |

4000~5000 |

20000~22000 |

8000~12000 |

|

Thermal conductivity |

1.2W/mK |

0.9W/mK |

1.0W/mK |

1.2W/mK |

|

Volume Resistivity |

100TΩ-cm |

100TΩ-cm |

110TΩ-cm |

< 0.0003 TΩ-cm |

|

Curing conditions |

180min/180℃ |

170min/120℃ |

80min/160℃ |

RT30min/175min 175min/120℃ |

|

Shelf Life |

12Months |

12Months |

12Months |

12Months |

Package:10g /100g /300g

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly’s silicone sealant is a 100% silicone formulation that creates a tough, watertight, mildew resistant seal, long service life in adverse environments, is flexible, is resilient across a wide temperature range, excellent electrical insulating qualities, enhanced comfort and feel. It can also be formulated to meet the requirements of sensitive applications, such as automotive, aerospace, appliance, business machine, electrical and consumer industries.

|

Specification / Model |

TY-102 |

TY-104 |

TY-105 |

TY-108 |

|

Appearance |

Black |

Translucent |

Black |

Gray |

|

Features |

Provides superior protection from moisture, thermal stress, impact and cures fast |

Good adhesion, application for electronic device sealing and waterproofing. |

Easily seals internal combustion engine parts |

Good durability for lubricating oil, engine oil, and water |

|

Viscosity(Pa.s) |

Paste |

Semi-fluid |

Paste |

Paste |

|

Shore A |

35 |

30 |

40 |

45 |

|

Surface Curing Time |

25min |

5~10min |

50min |

30min |

|

Total Curing Time |

24Hr |

24Hr |

24Hr |

24Hr |

|

Tensile Strength |

≧3.0Mpa |

≧2.0Mpa |

≧2.0Mpa |

≧2.0Mpa |

|

Maximum Gap Fill |

6mm |

6mm |

6mm |

6mm |

|

Service Temperature |

-60~200℃ |

-60~200℃ |

-60~200℃ |

-60~200℃ |

Package:85g / 310ml

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly Epoxy is a one-part and two-part adhesive consisting of an epoxy resin and a hardener. Tightly Epoxy can be used as an adhesive for a wide range of materials as a versatile filler for gap filling, surface repairs, and laminating. The resin and hardener formulas, ingredients, combinations, are tested to compare fatigue strength, glass transition temperature, and peak exotherm. It can be formulated to meet the requirements of sensitive applications, such as automotive, aerospace, electrical and industries.

Electronics, Key pad, Mobile phone, OA machine, Electric appliance, Electronic component.

It can provide good durability, anti-aging and good water resistance.

Apply in metal, ceramic, wood, glass and plastic between the package bonding, with excellent bonding strength.

Not suitable for elastic or soft material products.

|

Specification / Model |

TY-201 |

TY-202 |

TY-203 |

TY-205 |

|

Appearance |

Black |

Black |

Black |

Black |

|

Applicable |

For low temperature fast curing lens module process |

For underfilling, fast flow, rework |

For PCB component fixing and high temperature process |

High temperature bond metal, ceramic, plastic |

|

Viscosity(mPa.s) |

25000~33000 |

2000~5000 |

30000~45000 |

35000~40000 |

|

Curing temperature |

80℃ |

120℃ |

120℃ |

150℃ |

|

Curing Time |

30min |

10min |

60min |

40min |

|

Shore D |

D77 |

D70±2 |

D80±2 |

D75±2 |

|

Storage temperature |

2~8℃ |

2~8℃ |

-20℃ |

5~10℃ |

|

Coating Method |

Dispensing |

Dispensing |

Dispensing |

Dispensing |

|

Shelf Life |

12Months |

12Months |

12Months |

12Months |

Package:30g / 1000g

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly provides Polyurethanes (Urethane Resin- PU), a polymeric, flexible, insulating, hard and chemically resistant (Acid—Alkali—Salty water) conformal coating. These are used to protect electronic parts from chemical corrosion, oil, moisture, fungus, and static discharges. Polyurethane coatings are supplied as single or two-component formulas. These coatings are suitable for printed circuit board applications such as sensors in the oil and gas industry, automotive, agriculture and common electronics.

For bonding and fixing electronic components, handicrafts and gifts.

It can provide good durability, anti-aging and good water resistance.

Excellent bonding for packaging bonding between metal, ceramics, wood, glass and hard plastic.

Electronic or other products used for fast bonding and fixing can be used.

|

Specification / Model |

TY-301 |

TY-302 |

TY-303 |

TY-305 |

|

Appearance |

Transparent |

White (1:1) |

Gray (1:1) |

Transparent (1:1) |

|

Applicable |

For the conformal coating of electronic products, with good waterproof |

Strong, tough, and can be used for bonding a variety of materials |

Strong, tough, and meets the requirements of high shear force |

High transparency, good flexibility, used for sealing and waterproofing |

|

Viscosity(mPa.s) |

8000~10000 |

38000~45000 |

20000~27000 |

15000~20000 |

|

Curing temperature |

25℃ |

25℃ |

25℃ |

25℃ |

|

Curing Time |

10min |

20min |

40min |

5min |

|

Shore D |

A50 |

D60±2 |

D60±2 |

A50±2 |

|

Storage temperature |

2~8℃ |

25℃ |

25℃ |

25℃ |

|

Coating Method |

Dispensing |

Dispensing |

Dispensing |

Dispensing |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:30g / 1000g

※To learn more information, please visit our Safety Data Sheet (SDS)

The UV curing adhesive provided by Tightly has high strength, high stability, good flexibility, low curing temperature, fast speed, and small shrinkage rate. It is ideal for many applications in which glass or plastic are used; these are able to convey UV or visible light that is bonded to itself or metals and other substrates. In many industries, manufacturers often desire the fastest cure process available, such as automotive, aerospace, electrical and industries.

Used in electronics, electrical, automotive and aviation industries.

Solvent-free, Non-flammable, increase safety.

Cure Only When Exposed to Light–permits alignment of parts prior to bonding.

Single Part Product, No mixing required.

|

Specification / Model |

TY-401 |

TY-403 |

TY-405 |

TY-407 |

|

Appearance |

Transparent |

Brown |

Amber |

Transparent |

|

Applicable |

Optical glass and filter bonding, suitable for optical lens vehicle, display |

For PVC, PC, ABS, PU low viscosity products |

For glass and metal |

High temperature durable, waterproof, moisture-proof curing |

|

Viscosity(Pa.s) |

4000~5000 |

500~1500 |

15000~18000 |

45000~55000 |

|

Curing conditions(Mj/cm²) |

3000~4000 Mj/cm² |

2000 Mj/cm² |

2500 Mj/cm² |

>3000 Mj/cm² |

|

Shore D |

D40 |

D30 |

D60 |

A30±3 |

|

Shear strength |

7 |

>3.5 |

>10 |

>1 |

|

Service Temperature |

-40~120℃ |

-15~100℃ |

-50~130℃ |

-50~200℃ |

|

Coating Method |

Dispensing |

Dispensing |

Dispensing |

Dispensing |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:30g / 1000g

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly provides conformal coating solutions, including silicone, acrylic, polyurethane, epoxy resin and UV curing coating. It has excellent electrical insulation properties and chemical stability, as well as moisture resistance, heat resistance, oil resistance, and resistance to conductors and other materials. There are several options for coating technologies; brushing, dipping or spraying improve electronics. This product has good compatibility and is fully used in the electronic assembly technology industry and the optoelectronic industry.

For laptops, servers, large-size LCD TVs, motors, etc.

For (flexible, rigid) circuit boards, aviation instruments, industrial control boards, semiconductor circuit protection, home appliance controllers, and electronic parts.

Used in the coating process of consumption, protection, aviation, ships and automobiles.

|

Specification / Model |

TY-501 |

TY-502 |

TY-505 |

TY-508 |

|

Based |

Acrylic |

Silicone |

Polyurethane |

UV Coating |

|

Applicable |

Fast curing, flexible and easy to repair, which can provide the best moisture protection |

Faster curing, works against humidity and harsh environments with moisture protection |

It protects against moisture, fungus, dirt, dust, thermal shock, abrasion, and short circuits |

The next generation of VOC-free conformal coating. Curing within seconds of UV light |

|

Appearance |

Transparent |

Transparent |

Transparent |

Transparent |

|

Solid content(%) |

35% |

60% |

55% |

60% |

|

Dielectric strength |

45Kv/mm |

55Kv/mm |

50Kv/mm |

50Kv/mm |

|

Volume resistivity |

5.0x 1015 |

5.0x 1013 |

5.1x 1014 |

6.0x 1015 |

|

Curing Time |

10~15min |

8~10min |

15~20min |

10~15min |

|

Service Temperature |

-55~125℃ |

-60~200℃ |

-55~130℃ |

-55~125℃ |

Package:30g / 1000g

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly’s formula provides impact resistance and faster setting for extra durability, and extra fast adhesion. Available in liquid and gel varieties. Tightly’s super glue liquids are ideal for penetrating hard-to-bond cracks on non-porous surfaces. It provides impact resistance and faster setting for extra durable, extra fast adhesion. Tightly super glue gel is a specially formulated rubber toughened instant adhesive that resists impact, shock, vibration and temperature extremes. It is ideal for bonds leather, cork, paper, cardboard, wood, fabric, metal, ceramic, rubber and hard plastics such as acrylic, polycarbonate, polystyrene and PVC.

Electronics, Key pad, Mobile phone, OA machine, Electric appliance, Electronic component.

It is very durable.

Apply in metal, ceramic, wood, glass and plastic bonding, with excellent bonding strength.

Provide selection of liquid, and gel viscosity products.

|

Specification / Model |

TY-601 |

TY-602 |

TY-604 |

TY-606 |

|

Applicable |

For wood, leather, cloth, cardboard, metal, plastic |

For Cosmetics, Lamp Shades |

For difficult-to-bond items |

For metal, rubber, plastic |

|

Viscosity(Pa.s) |

100~200 |

1000~1500 |

100,000~200,000 |

2000~2500 |

|

Odor |

Mild Pungent |

Mild |

Mild Pungent |

Mild Pungent |

|

Surface Curing Time |

1~3sec |

15~30sec |

< 60sec |

< 60sec |

|

Accelerated curing |

< 1sec |

< 5sec |

< 15sec |

< 15sec |

|

Tensile strength (N.m) |

20 |

22 |

25 |

26 |

|

Service Temperature |

-50~80℃ |

-50~70℃ |

-60~120℃ |

-50~120℃ |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:20g / 500g

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly threadlocker is designed for high, medium, low strength locking and sealing. The product cures when confined in the absence of air between close fitting metal surfaces. It protects threads from rust and corrosion, and prevents loosening from shock and vibration.

High Strength Threadlocker, ideal for high vibration applications such as power sports, heavy equipment, automotive, and industrial applications.

Medium Strength Threadlocker, ideal for all nut and bolt applications 1/4” to 3/4” (6mm ~ 20mm). Locks and seals while preventing parts loosening due to vibration. Protects threads from corrosion. Removable with hand tools for easy disassembly.

Low Strength Threadlocker, designed for fasteners under 1/4”(6mm) that require occasional adjustment. Removable with hand tools for easy disassembly.

|

Specification / Model |

TY-701 |

TY-702 |

TY-703 |

TY-705 |

|

Applicable |

Low Strength threadlocker Purple |

Medium Strength threadlocker Purple |

High Strength threadlocker Red |

High Strength threadlocker Red |

|

Features |

Under 1/4”(6mm) |

Applications 1/4” to 3/4” (6mm~20mm) |

For heavy equipment, automotive, and industrial |

For heavy equipment, automotive, and industrial |

|

Viscosity(Pa.s) |

1200~2000 |

1200~5000 |

1200~7000 |

400~600 |

|

Set Time |

20min |

25min |

30min |

30min |

|

Cure Time |

24 Hours |

24 Hours |

24 Hours |

24 Hours |

|

Breakaway Torque (N.m) |

6 |

16 |

22 |

25 |

|

Service Temperature |

-50~150℃ |

-50~150℃ |

-15~200℃ |

-15~200℃ |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:50ml /250ml /1000ml

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly’s Peelable Solder Mask provides printed circuit boards with protection in soldering processes like wave soldering, reflow soldering, or at the PCB level a surface finish protection. It is a temporary, high viscosity, fast curing, peelable solder masking agent. Including multi-surface finishes such as carbon ink, hard gold or a bondable gold need protection from the balance of the surface finishing being applied such as ENIG or Immersion Silver.

Time and cost-saving process compared to taping.

Non-contaminating, non-staining, and non-corrosive.

Thicker coating does not seep through thru-holes.

Peelable Solder Masks(strippable mask or blue-mask) are applied by screen-printing, act as in-process protection and are removed after processing.

|

Specification / Model |

TY-801 |

TY-803 |

TY-804 |

TY-805 |

|

Appearance |

White |

White |

White |

Blue |

|

Density(g/ml) |

0.9±0.05 g/ml |

0.85±0.05 g/ml |

0.9±0.05 g/ml |

0.95±0.05 g/ml |

|

Viscosity(Pa.s) |

9000~13000 |

5000~9000 |

8000~15000 |

8000~13000 |

|

Cure Time @25℃ (2mm Thickness) |

30~45min |

30~40min |

45~60min |

45~60min |

|

Cure Time @60℃ (2mm Thickness) |

15~20min |

15~20min |

15~30min |

15~30min |

|

Tensile strength (Mpa) |

≧0.5 |

≧0.5 |

≧0.5 |

≧0.5 |

|

Service Temperature |

-50~150℃ |

-50~150℃ |

-50~150℃ |

-15~200℃ |

|

Shelf Life |

6 Months |

6 Months |

6 Months |

6 Months |

Package:250ml /Tube

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly’s PUR Hot Melts offer a very strong initial bond and after the adhesive sets, polyurethane hot melt bonds continue to strengthen as they react with moisture in the air. PUR is an excellent adhesive for product assembly and manufacturing applications. Polyurethane hot melts work quickly to form an extremely strong bond, with a fast set time. Include strength, flexibility, temperature and chemical resistance. PUR can be used in a wide range of industries and has many applications.

Aerospace, automotive, consumer, and medical products.

Woodworking, furniture making, construction, and product assembly.

Non-toxic, longer open time, very strong bond, easy to dispense.

|

Specification / Model |

TY-901 |

TY-903 |

TY-905 |

TY-908 |

|

Appearance |

Translucent |

Opaque white |

White |

Black |

|

Viscosity(Pa.s) |

3000 |

6000 |

6000 |

6500 |

|

Specific Gravity |

1.1 |

1.1 |

1.15 |

1.15 |

|

Solid content(%) |

100% |

100% |

100% |

100% |

|

Cure Type |

Moisture Cure |

Moisture Cure |

Moisture Cure |

Moisture Cure |

|

Tensile strength (Mpa) |

8 |

7.5 |

8.2 |

8 |

|

Temperature range |

100~110℃ |

110~120℃ |

110~120℃ |

110~120℃ |

|

Open time(min) |

2~4min |

2~4min |

2~4min |

2~4min |

|

Softening range |

65±10°C |

65±10°C |

65±10°C |

65±10°C |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:30ml /300ml

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly manufactures a variety of products for hot-melt adhesives. Available with a variety of processing characteristics, properties can include low odor, good solubility, and excellent heat stability. Hot Melt Adhesives are 100% solid thermoplastic resins that liquefy when heated. When applied to a surface, they cool, harden, and reach their bond strength within seconds. Hot melt adhesive applications are incredibly diverse. The adhesive is used in manufacturing hygiene, furniture, and packaging products as well as in medical, electronic, and automotive applications.

Aerospace, automotive, consumer, and medical products.

Woodworking, furniture making, construction, and product assembly.

Non-toxic, easy to dispense.

|

Specification / Model |

TY-951 |

TY-961 |

TY-971 |

TY-981 |

|

Base |

EVA |

TPU |

Polyolefin |

Polyamide |

|

Appearance |

White /Amber |

White /Amber |

White /Amber |

White /Amber |

|

Shape |

Stick /Pellet |

Stick /Pellet |

Stick /Pellet |

Stick /Pellet |

|

Softening Point |

80±5℃ |

80±5℃ |

145±5℃ |

150±5℃ |

|

Melting Point |

150℃ |

160℃ |

170℃ |

170℃ |

|

Viscosity(Pa.s) |

4500~6500 |

4500~6500 |

2500~4500 |

2500~4500 |

|

Set Time |

8~15 Sec |

8~15 Sec |

5~15 Sec |

5~15 Sec |

|

Open time |

45 Sec |

80 Sec |

60 Sec |

70 Sec |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:25Kg

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly 's structural adhesives provide reliable, long-lasting bonding and sealing where load-bearing and other structural conditions exist. A structural adhesive is an adhesive which “hardens” or cures into a material capable of holding two or more substrates together. Structural adhesives include epoxies, acrylics, polyurethanes, cyanoacrylates, and urea-formaldehydes. The product may undergo shock, vibration, chemical exposure, temperature excursions or many other types of potentially weakening or destructive agents, and still be bonded.

Aerospace, automotive, consumer, and medical products.

The same, or quite different, ranging from metals, plastics, glass, rubbers, ceramics or composites.

Battery assembly.

Low odor, high strength.

|

Specification / Model |

TY-1001 |

TY-1002 |

TY-1003 |

TY-1005 |

|

Base |

Epoxy |

Acrylic |

Acrylic |

Acrylic |

|

Features |

Low odor, high strength, for laptops, transportation, rail, and panels |

Low odor, medium strength, for laptops, transportation, rail, and panels |

Low odor, medium strength, for laptops, transportation, rail, and panels |

Medium viscosity, high strength, for motor core |

|

Viscosity(Pa.s) |

15000~23000 |

25000~35000 |

50000~60000 |

12000~20000 |

|

mixing ratio |

1:1 |

1:1 |

10:1 |

1:1 |

|

Cure Time |

5min |

10min |

5min |

10min |

|

Tensile strength (Mpa) |

22 |

21 |

22 |

23 |

|

Shore D |

D60 |

D65±2 |

D60±2 |

D62±2 |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:50ml /Tube

※To learn more information, please visit our Safety Data Sheet (SDS)

Tightly's general purpose resin is a polyester resin specially formulated with Thixotropic Ingredients for increased viscosity and Non-sag properties. Our general purpose resin is top quality, pre-accelerated, thixotropic, Orth phthalic resin suitable for both hand lay up and gun spray up. The resin offers excellent mechanical properties, impact and water resistance. The resin is used in boat building, repair, roofing, casting, electronic, automotive applications and more.

Electronic, automotive, fibreglass, and casting products.

For small industrial to super-yachts.

For boat building & repairs.

|

Specification / Model |

TY-1101 |

TY-1102 |

TY-1103 |

TY-1105 |

|

Base |

Solvent |

Solvent |

Solvent |

Water |

|

Appearance |

Amber |

Transparent |

Black |

Transparent |

|

Features |

For PVC, ABS, PC, metal. Used in furniture, leather and lampshade |

For PP, PU, PET, metal. Used in crafts and gifts |

For PVC, ABS, PC, metal. Used in furniture, leather and lampshade |

Used in furniture, leather and crafts, better working environment |

|

Viscosity(Pa.s) |

600~900 |

1200~2000 |

1500~25000 |

500~1000 |

|

Odor |

Mild |

Mild |

Mild |

Mild |

|

Cure Time |

20min |

30min |

10min |

25min |

|

Specific Gravity |

1.1±0.05 |

1.1±0.05 |

1.15±0.05 |

1.15±0.05 |

|

Shelf Life |

12 Months |

12 Months |

12 Months |

12 Months |

Package:1KG /5KG /20KG

※To learn more information, please visit our Safety Data Sheet (SDS)

ST-S01 High Performance Cleaner is specially formulated to be used. It removes hard to clean silicone, epoxy, UV adhesive, threadlocker etc. This product is rugged enough for industrial maintenance and cleaning applications.

Package:500ml /1000ml /4L /20L

※To learn more information, please visit our Safety Data Sheet (SDS)

ST-S04 General Purpose Cleaner is specially formulated to remove hard to clean silicone, epoxy, UV adhesive, threadlocker etc. This product is rugged enough for industrial maintenance and cleaning applications.

Package:500ml /1000ml /4L /20L

※To learn more information, please visit our Safety Data Sheet (SDS)

ST-905 Conformal coating thinner is designed to alter the makeup of coatings for ease of application, typically adjusting the coatings' solids content or viscosity. ST-905 thinners may also be used to clean metal equipment found in the coating process including spray guns and dip coating machines.

Package:4L /20L

※To learn more information, please visit our Safety Data Sheet (SDS)

| Gauge | 14G | 15G | 18G | 20G | 21G | 22G | 23G | 25G | 27G | 30G |

| Inner diameter (mm) | 1.55 | 1.37 | 0.84 | 0.6 | 0.51 | 0.41 | 0.33 | 0.25 | 0.2 | 0.15 |

| Gauge | 14G | 15G | 18G | 20G | 21G | 22G | 23G | 25G | 27G | 30G |

| Inner diameter (mm) | 1.55 | 1.37 | 0.84 | 0.6 | 0.51 | 0.41 | 0.33 | 0.25 | 0.2 | 0.15 |

| Gauge | 14G | 15G | 18G | 20G | 21G | 22G | 23G | 25G | 27G | 30G |

| Inner diameter (mm) | 1.55 | 1.37 | 0.84 | 0.6 | 0.51 | 0.41 | 0.33 | 0.25 | 0.2 | 0.15 |

| Gauge | 20G | 25G | 27G |

| Inner diameter (mm) | 0.6 | 0.25 | 0.2 |

| Gauge | 14G | 15G | 18G | 20G | 21G | 22G | 23G | 25G | 27G | 30G |

| Inner diameter (mm) | 1.55 | 1.37 | 0.84 | 0.6 | 0.51 | 0.41 | 0.33 | 0.25 | 0.2 | 0.15 |

| Gauge | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 80 |

| Inner diameter (mm) | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.8 |

| Gauge | 14G | 15G | 18G | 20G | 21G | 22G | 23G | 25G | 27G | 30G |

| Inner diameter (mm) | 1.6 | 1.37 | 0.84 | 0.6 | 0.51 | 0.41 | 0.36 | 0.25 | 0.2 | 0.15 |

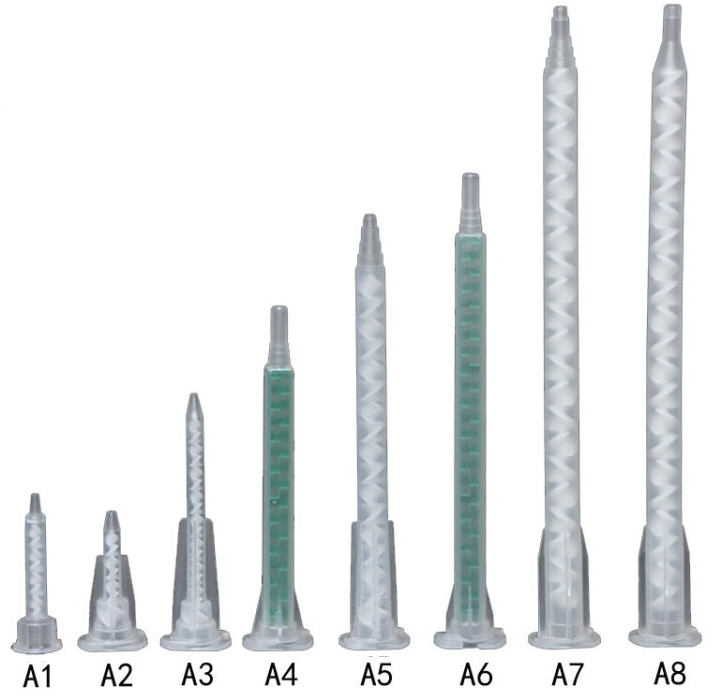

| Gauge | Element | Inside | Length | Glue Diameter |

| A1 | 8 | 3.0mm | 38mm | 1mm |

| A2 | 8 | 3.0mm | 38mm | 1mm |

| A3 | 17 | 3.0mm | 62.2mm | 1mm |

| A4 | 16 | 5.3mm | 83mm | 1.5mm |

| A5 | 17 | 5.4mm | 103.6mm | 1.5mm |

| A6 | 24 | 5.3mm | 115mm | 1.5mm |

| A7 | 21 | 6.3mm | 153mm | 1.5mm |

| A8 | 21 | 6.3mm | 153mm | 1.5mm |

| Size | 1ml | 3ml | 5ml | 10ml | 20ml | 30ml | 50ml | 100ml | 150ml | 200ml | 250ml | 300ml | 400ml | 500ml |

| Cap | Luer Lock | |||||||||||||

The Tightly dispensing gun, made of solid plastic, is for use with one-part system cartridges. It features an easy snap-in / snap-out cartridge insertion system that facilitates cartridge installation in seconds. Simply pull the trigger and obtain exactly the amount of material needed to complete your task.

Dispenser Conveyor Gun 50ml,Adhesive Dispensing Mixer, Manual Dual Cartridge Applicator AB Gun 1:1/2:1/10:1 Ratio. Automatic mixing and delivery of impression materials are made easy with this handgun cartridge dispenser. Used for smearing or dripping various two-component adhesives or coatings to solve the problem of uneven mixing of two-component adhesive products.